Amorphous

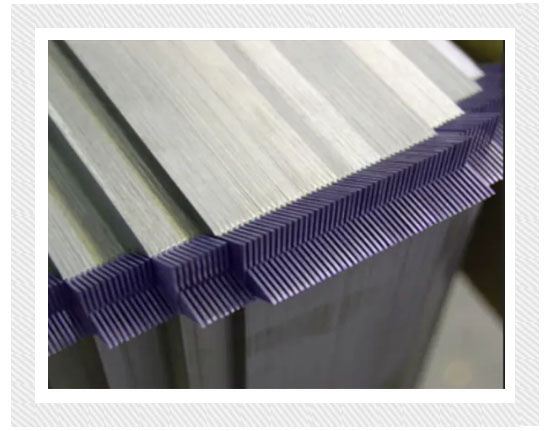

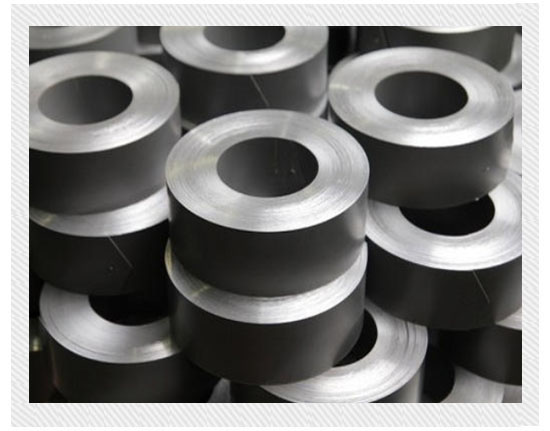

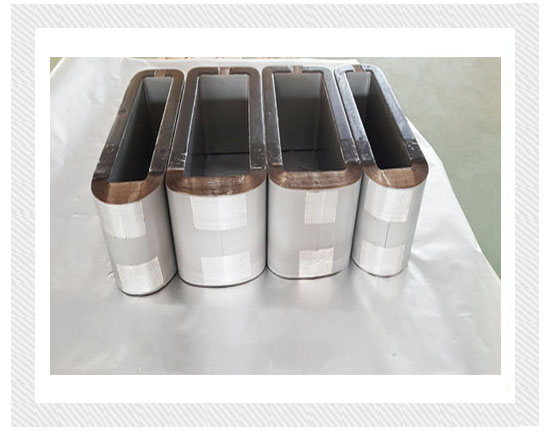

The amorphous is a non-crystal substance created by rapidly freezing liquids of high temperature. Because there is no rule of atomic arrangement, the energy loss (hysteresis loss) is small when the flux of magnetic induction passes the iron core. In addition, eddy current loss is decreased because the thickness is approximately 0.03 mm, which is about 1/10 comparing with silicon steel. Therefore, the no-load loss (eddy current loss and hysteresis loss) can be decreased to about 1/5 of silicon steel. In transformers with amorphous cores, a ribbon of amorphous steel is wound to form the core. T.I Industries produces high-quality amorphous distributed gap (wound) cores according to Customer specification for single-phase and three-phase distribution transformer applications By using Metglas® amorphous metal. Epoxy coating is applied to some parts of the cores in order to get mechanical rigidity.

Features :

The coils are easy to assemble with bonded edges for core integrity and transformer reliability. The magnetic field is annealing for stress relief and magnetic property optimization, while the cores are 100 percent tested to prevent consistent transformer loss performance. Coil Technology plays a key role in the production of cost-effective AMTs. The materials and processes are focused on maximum performance and minimum quantities. The high axial and radial fill factors minimize conductor and core costs while maximizing short circuit strength. It also precisely gives dimensional control during winding and finishing to minimize coil clearances.

-

01 Detail

These products are manufactured using the best quality raw material and the most advanced techniques by our trustworthy vendors in order to meet the preset international standards. Further, the offered range is stringently tested on various parameters by their skilled quality controller team using latest testing tools.

-

02 Basic Characteristics

. The amorphous alloy has a saturation flux density of 1.56T with working flux density up to 1.4T

. The density of amorphous material is 7.18 gm/cc

. The thickness of the amorphous ribbon is 0.025 mm

. Lamination factor of 86%

. The specific core loss of amorphous metal is 0.1-0.2 watt/kg at 1.4 T

. Available in a standard width of 142 mm, 170 mm and 213 mm

. Need annealing at 340-360 deg C